Products

Square Magnets for All Types of Electrical Motors and Generators

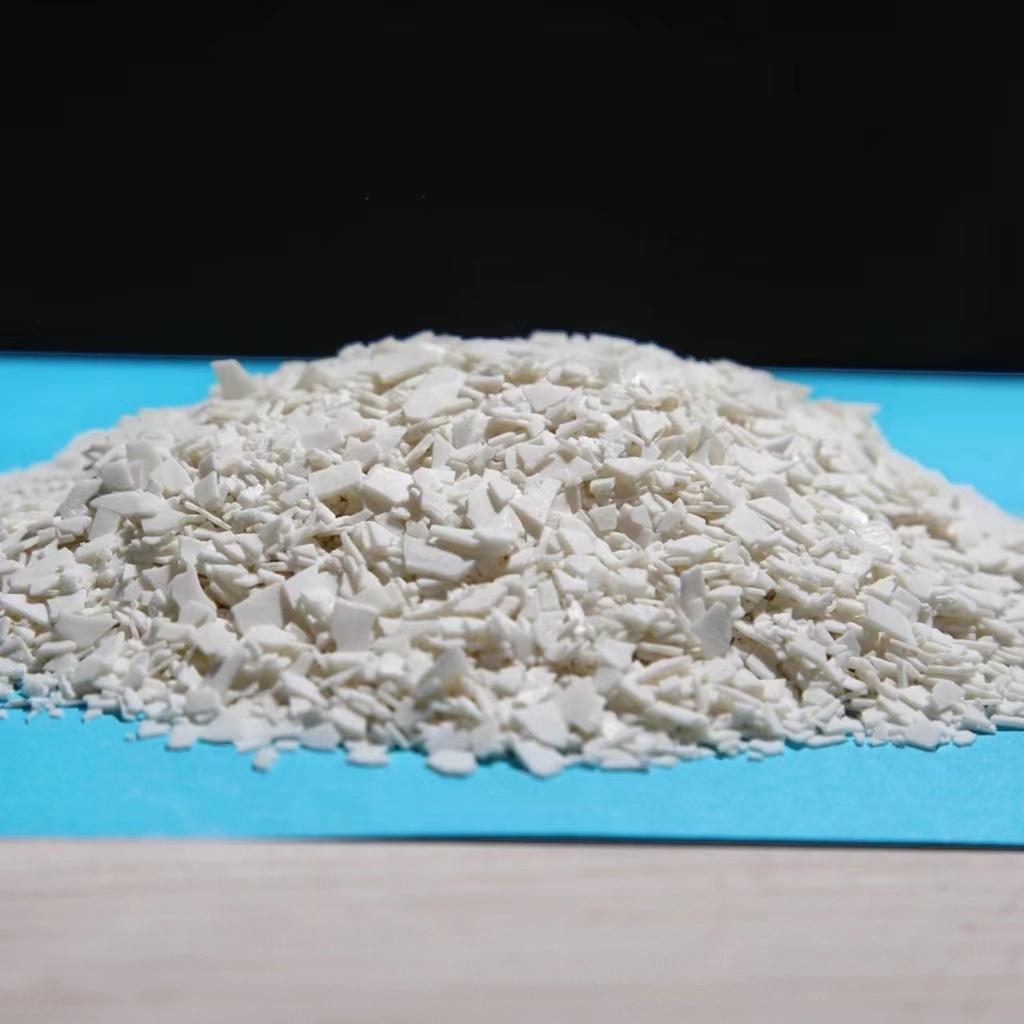

Mainly used for lift motor/linear motor/air-conditioner compressor motor/wind power generator. The material grade are mostly from H to SH. Based on customer requirement, we can make the machining tolerance within +/-0.05mm. The coating type is generally Zn/NiCuNi/Phosphate/Epoxy and NiCuNi+Epoxy.

The high magnetic energy product and high coercivity (especially high intrinsic coercivity) of neodymium iron boron make rare earth permanent magnet motors have a series of advantages such as small volume, light weight, high efficiency, and good characteristics.

The improvement of energy efficiency standards promotes upgrading and upgrading, and frequency conversion technology has gradually replaced fixed frequency technology. Neodymium iron boron permanent magnet materials are mainly used in frequency conversion compressors in the field of household appliances, achieving an overall energy-saving effect of over 30%. At the same time, it has a significant effect on reducing noise and extending the service life of air conditioning.

1.How to design and select the most cost-effective magnet that meets customer needs?

Magnets are classified into different grades based on their ability to withstand temperature; According to different usage requirements, the same brand is divided into different performance levels, and different performance levels correspond to different performance parameters. In general, designing and selecting the most cost-effective magnet requires the customer to provide the following relevant information,

▶ Application fields of magnets

▶ Material grade and performance parameters of the magnet (such as Br/Hcj/Hcb/BHmax, etc.)

▶ The working environment of the magnet, such as the normal working temperature of the rotor and the maximum possible working temperature

▶ The installation method of the magnet on the rotor, such as whether the magnet is surface mounted or slot mounted?

▶ Machining dimensions and tolerance requirements for magnets

▶ Types of magnetic coating and anti-corrosion requirements

▶ Requirements for on-site testing of magnets (such as performance testing, coating salt spray testing, PCT/HAST, etc.)