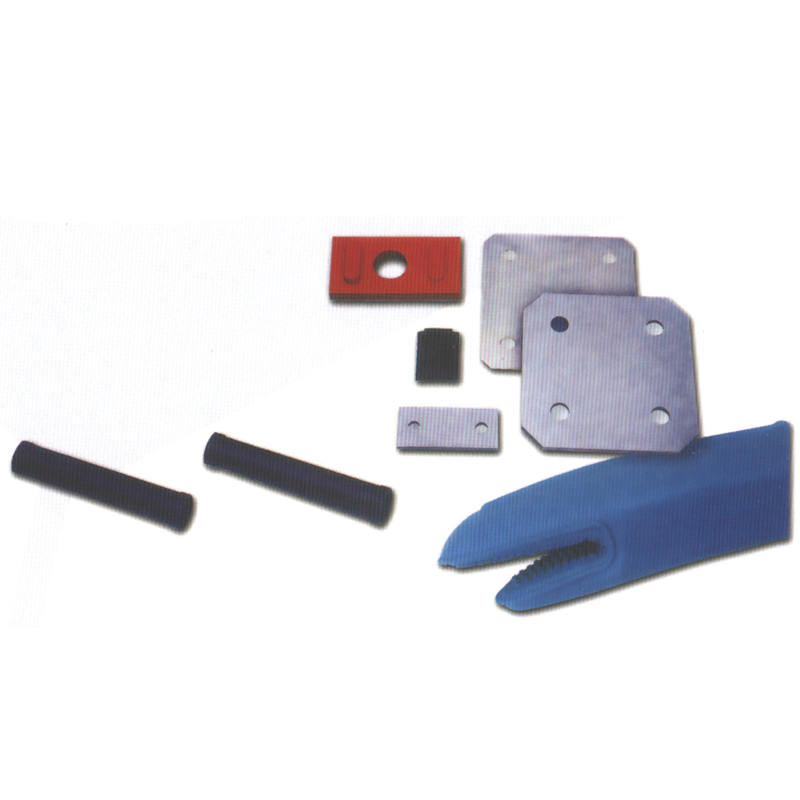

Products

Standard Silicone Rubber for Molding

| Data/Item/Type | HE-7130 | HE-7140 | HE-7150 | HE-7160 | HE-7170 | HE-7180 |

| Appearance | translucent,no obvious extraneous matter | |||||

| Density(g/cm³) | 1.08±0.05 | 1.13±0.05 | 1.15±0.05 | 1.19±0.05 | 1.22±0.05 | 1.25±0.05 |

| Hardness(Shore A Points) | 30±3 | 40±3 | 50±3 | 60±3 | 70±3 | 80±3 |

| Temsile Strength(Mpa≥) | 6.5 | 7.0 | 7.5 | 7.5 | 6.5 | 6.0 |

| Elongation at Breakage(%≥) | 500 | 450 | 350 | 300 | 200 | 150 |

| Tension Set | 7 | 7 | 8 | 8 | 7 | 6 |

| Tear Strength(kN/m≥) | 15 | 16 | 18 | 18 | 17 | 16 |

First vulcanization condition for test piece:175℃x5min

Vulcanizator:80% DMDBH,quantity added 0.65%

We adhere to the principle of Customer First, Quality First, continuous improvement, mutual benefit and win-win. In cooperation with customers, we try our best to provide customers with the highest quality of service. We We are committed to building our own brand and reputation. At the same time, we sincerely welcome new and old customers to visit our company and negotiate business.

With rich manufacturing experience, high-quality products and perfect after-sales service, the company has won a good reputation and has become one of the well-known enterprises specializing in the production of series products. We sincerely wish to establish business relations with you for our mutual benefit.

Our company will, as always, adhere to the principle of “quality first, reputation first, customer first” and serve customers wholeheartedly. Warmly welcome friends from all walks of life to visit and guide, work together to create a brilliant future!

1.How To Choose PVC Heat Stabilizer In Plastic Formulation Design

The main reason for adding PVC heat stabilizer in plastic formulation design is that it can capture the autocatalytic HCL released by PVC resin, which can be reflected by the addition of unstable polyene structure generated by PVC resin, so as to prevent or reduce the decomposition of PVC resin. In order to better solve the PVC processing may occur in a variety of undesirable phenomena.

The PVC heat stabilizer selected in the general formula should be considered according to its own characteristics, functions and requirements of products. For example, the lead salt compound stabilizer mainly used in hard products has the characteristics of good thermal stabilizer, excellent electrical performance and low price. Disadvantages are toxicity, easy to pollute products, can only produce opaque products.

Calcium zinc composite stabilizer can be used as a non-toxic stabilizer, used in food packaging and medical equipment, drug packaging, but its stability is relatively low, calcium stabilizer dosage when poor transparency, easy to spray frost. Calcium and zinc composite stabilizer generally use polyol and antioxidant to improve its performance.

The above two types of PVC thermal stabilizers are commonly used at present, but the practical application is not limited to this, but also contains organic tin thermal stabilizers, epoxy stabilizers, rare earth stabilizers and hydrotalcite stabilizers.

2.What Should Be Paid Attention To When Using Calcium And Zinc Stabilizer

Due to its unique advantages, calcium and zinc stabilizer is widely used in the production process of a variety of commodities, but in the use of it must follow the use of precautions, about its precautions we follow hang long experts to fully understand.

Precautions for use of calcium and zinc stabilizer

1. The PH value of the working solution of calcium and zinc stabilizer should be kept within the range of 6-9. If it is beyond this range, the active ingredients will precipitate into particles and the appearance and texture will decline. Therefore, keep the working environment clean and prevent acidic or alkaline components from entering the working fluid.

2. Water bath must be used to heat the working fluid. Higher temperature can help the effective ingredients penetrate into the coating and increase the texture. In order to prevent the decomposition of the working fluid, the heating rod should not be placed directly in the working fluid.

3, if the working fluid turbidity or precipitation is because of low PH. At this time, the sediment can be filtered out, with the help of ammonia water to adjust the PH value to about 8, and then with the help of n-butanol dissolve the active ingredients, add an appropriate amount of pure water can be recycled. However, after repeated use, the appearance and texture of the product will decline. If the texture requirements cannot be met, a new working fluid needs to be replaced.

3.How Much Do You Know About The Application Of Polyethylene Wax In Various Fields?

Polyethylene wax or PE wax is a tasteless, no corrosion chemical material, its colour is white small beads or flake, has higher melting point, high hardness, high gloss, color white, but also has excellent chemical stability, resistance to temperature at room temperature, resistance and excellent electrical properties, the size of the widely used, can be as modifier of chlorinated polyethylene material, plastic, textile coating agent as well as the improvement of oil and fuel oil viscosity increasing agent. It is widely used in many fields of industrial production.

1. Cable material: used as the lubricant of cable insulation material, it can enhance the diffusion of filler, improve the extrusion molding rate, increase the flow rate of mold, and facilitate the stripping.

2. Hot melt products: used for all kinds of hot melt adhesive, thermosetting powder coating, road sign paint, etc., as dispersant, it has good anti-sedimentation effect, and makes the products have good luster and three-dimensional sense.

3. Rubber: as the processing assistant of rubber, it can enhance the diffusion of filler, improve the extrusion molding rate, increase the flow rate of the mold, facilitate the demoulding, and improve the surface brightness and smoothness of the product after demoulding.

4. Cosmetics: make the products have the luster and three-dimensional effect.

5. Injection molding: enhance the surface gloss of products.

6. Powder coating: used for powder coating, which can produce patterns and extinction, and can resist scratches, wear and polishing, etc.; It can improve the dispersibility of pigment.

7. Concentrated color masterbatch and filling masterbatch: used as dispersant in color masterbatch processing and widely used in polyolefin masterbatch. It has good compatibility with PE, PVC, PP and other resins, and has excellent external and internal lubrication.

8. composite stabilizer, profile: in PVC, pipe, composite stabilizer, PVC profile, pipe fitting, PP, PE molding process as dispersant, lubricant and brightener, enhance the degree of plasticization, improve the toughness and surface smoothness of plastic products, and widely used in the production of PVC composite stabilizer.

9. Ink: as the carrier of pigment, it can improve the wear resistance of paint and ink, change the dispersion of pigment and filler, and have a good anti-sedimentation effect. It can be used as a flat agent for paint and ink, so that the products have a good luster and three-dimensional sense.

10. Wax products: widely used in floor wax, car wax, polish wax, candle and other wax products, to improve the softening point of wax products, increase its strength and surface gloss.