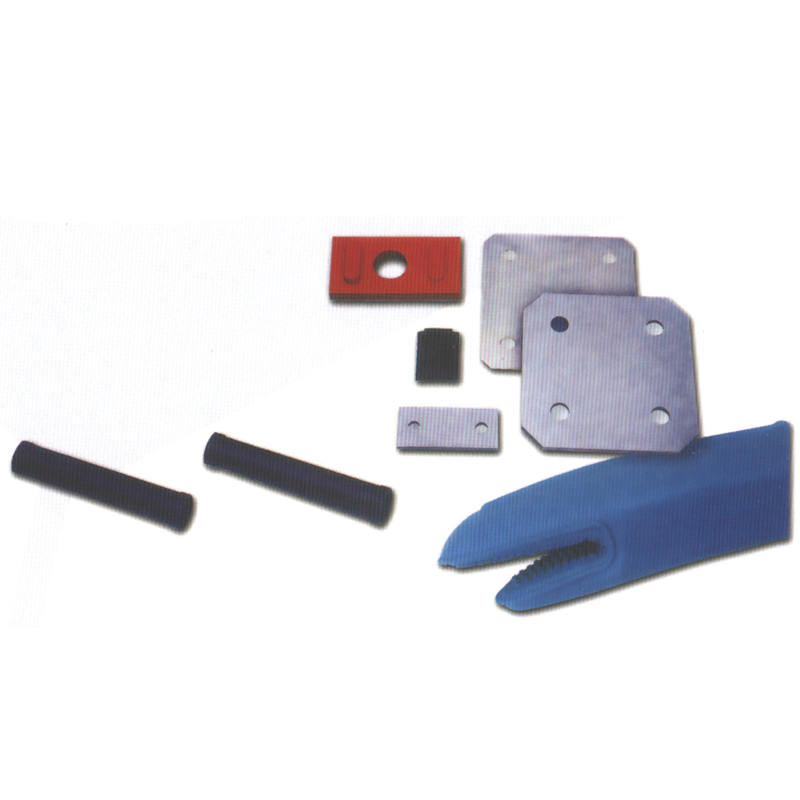

Products

General Purpose Vapour-phase Gum

| Data/Item/Type | 9120 | 9130 | 9140 | 9150 | 9160 | 9170 | 9180 |

| Appearance | translucent,no obvious extraneous matter | ||||||

| Density(g/cm³) | 1.02±0.04 | 1.08±0.05 | 1.12±0.05 | 1.14±0.05 | 1.16±0.05 | 1.18±0.05 | 1.22±0.05 |

| Hardness(Shore A Points) | 20±3 | 30±3 | 40±3 | 50±3 | 60±3 | 70±3 | 80±3 |

| Temsile Strength(Mpa≥) | 6.0 | 7.5 | 8.0 | 8.5 | 8.5 | 8.0 | 7.0 |

| Elongation at Breakage(%≥) | 700 | 650 | 600 | 500 | 400 | 300 | 150 |

| Tear Strength(kN/m≥) | 12 | 15 | 20 | 26 | 28 | 28 | 18 |

Physical and Mechanical Properties are based on first vulcanization data,Electrical Properties are drawn from second

vulcanization data.

First vulcanization condition for test piece:175℃x5min

Vulcanizator:80% DMDBH,quantity added 0.65%

Our products are made from the primary raw materials.Meanwhile, during the production, we constantly make the technology innovation and product optimization. In order to provide the better products and service for our customers, we make the strict management and control for the production process. Our product quality have received high praise from our customers. We are looking forward to establish a long business relationship with you.

Write your message here and send it to us