Products

NC foaming agent for WPC floor

Product Details

NC blowing agent is a kind of endothermic foaming agent, blow off the gas gently, make foaming process is easy to control, it can guarantee the stability of the performance especially in thicker size and complex shape dynamic molding process of foam products.

Technical data

| Product Code | Appearance | Gas evolution(ml/g) | Decomposition temperature (°C) |

| SNN-130 | white powder | 130-145 | 160-165 |

| SNN-140 | white powder | 140-160 | 165-170 |

| SNN-160 | white powder | 145-160 | 170-180 |

Feature

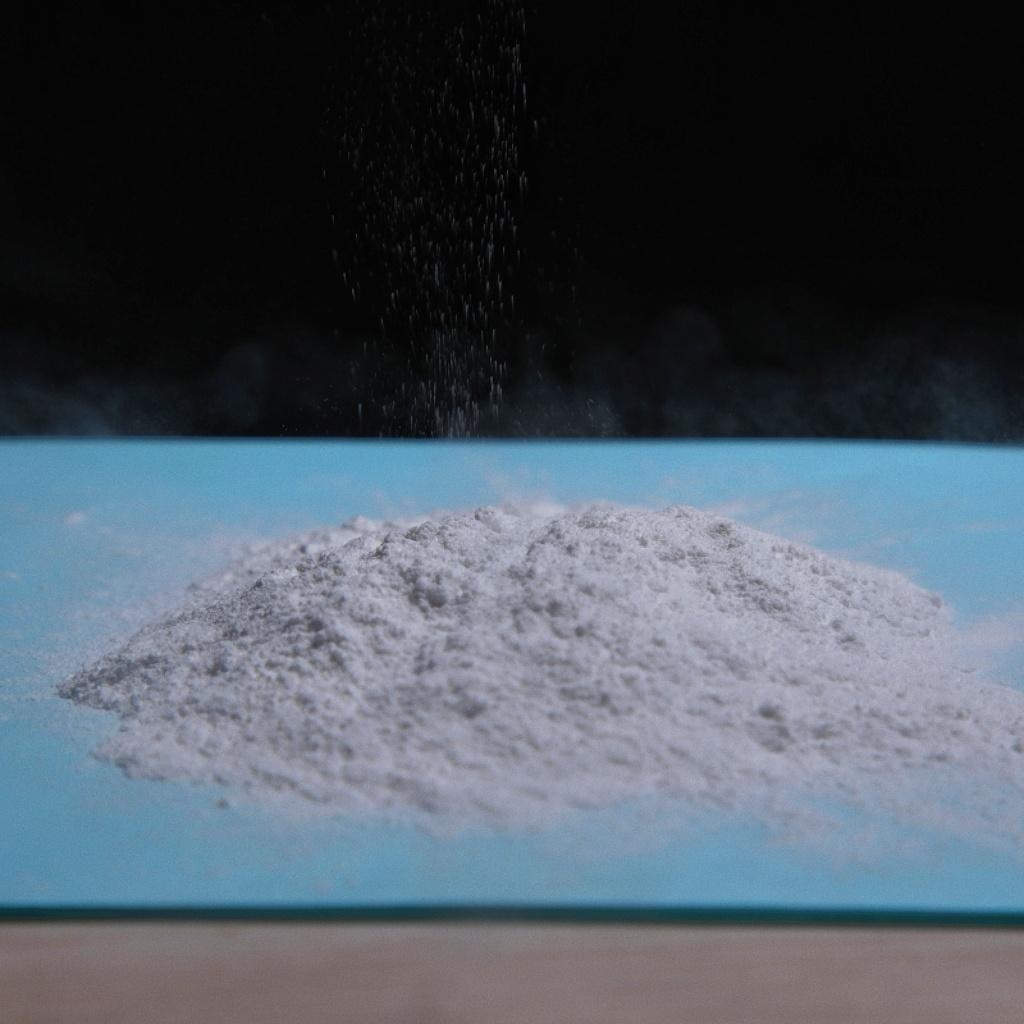

1. This product is white powder.

2. This product has excellent compatibility and good compatibility with AC foaming agent; it accelerates the decomposition of foaming agent, improves processing speed and reduces production cost.

3. This product can significantly improve the durability and aging resistance of the product, and ensure the long-term stability of the product.

4. This product can significantly improve the surface finish of the product. It does not show pinholes, air streaks and melting and cracking on the product surface.

5. This product is non-toxic, non-corrosive and environmentally friendly solid powder, no mechanical impurities, and non-dangerous goods.

Applications

WPC board floor

Packaging and storage

25kg/bag PP woven outer bag lined with PE inner bag

Unleash Efficiency and Performance with NC Foaming Agent for WPC Profiles

Introduction:

Welcome to the realm of limitless possibilities! In this article, we will embark on an extraordinary journey exploring the impressive capabilities of NC foaming agents in Wood-Plastic Composite (WPC) profiles. The application of NC Foaming Agent for WPC Profiles revolutionizes conventional manufacturing processes and allows for the creation of high-performing WPC profiles. Let’s delve into the advantages and discover how this innovative technology is reshaping the industry.

1. Enriched Strength-to-Weight Ratio

Strength and weight are fundamental considerations in material design, and NC Foaming Agent for WPC Profiles offers a remarkable solution. By integrating NC foaming agents into WPC profiles, manufacturers can achieve a higher strength-to-weight ratio, surpassing traditional materials like wood and metal. This exceptional combination ensures robust structures that are not only reliable but also significantly lighter, providing advantages in applications such as transportation and lightweight construction.

2. Streamlined Production Process

NC Foaming Agent for WPC Profiles streamlines the production process, enhancing efficiency and reducing costs. The foaming anonymized melt flow, ensuring consistent expansion and uniform distribution of bubbles during the foaming process. With improved flow properties, manufacturers can achieve faster cycle times, reduce material usage, and enhance productivity. Embrace this revolutionary additive to gain a competitive edge and meet the demands of today’s fast-paced market.

3. Enhanced Surface Finish and Aesthetics

In addition to their mechanical benefits, to traditional materials. The foaming process creates a microcellular structure on the surface, resulting in a visually pleasing texture that mimics natural wood grains or other desired finishes. Whether it’s a sleek and modern design or a rustic and timeless look, NC Foaming Agent for WPC Profiles offers endless customization possibilities, elevating the overall aesthetics and adding value to any project.

Discover the Benefits of NC Foaming Agent for WPC Profiles

1. Elevating Sound Absorption

Noise pollution is a common challenge faced by many industries. Fortunately, NC foaming agents offer a practical solution in the form of improved sound absorption capabilities. When integrated into WPC profiles, these agents facilitate effective noise reduction, making them an excellent choice for acoustic panels, flooring, and other noise-sensitive applications. Whether it’s in office spaces, schools, or residential buildings, NC Foaming Agent for WPC Profiles ensures a quieter and more serene environment.

2. Facilitating Customized Design Options

NC Foaming Agent for WPC Profiles provides an exciting opportunity for designers to unleash their creativity. The foaming process allows for greater flexibility in shaping WPC profiles, enabling the creation of complex and intricate designs that were previously unattainable. From unique patterns and textures to customized colors, NC foaming agents empower manufacturers to meet diverse market demands and deliver products that captivate and inspire.

In conclusion, NC Foaming Agent for WPC Profiles has revolutionized the WPC industry by enhancing lightweight durability, thermal insulation, sound absorption, and design possibilities. The integration of NC Foaming Agent for WPC Profiles opens up a world of opportunities for manufacturers, architects, and designers alike. Embrace the power of innovation and explore the limitless potential of NC foaming agents for a sustainable and remarkable future.

Unleashing the Potential of NC Foaming Agent in Wood-Plastic Composite Profiles

Introduction:

Welcome to an exciting world where science meets innovation! In this article, we will explore the fascinating realm of NC foaming agents and their significant role in enhancing Wood-Plastic Composite (WPC) profiles. The unique properties of NC Foaming Agent for WPC Profiles make them a game-changer, revolutionizing the WPC industry. Let’s dive deeper into this revolutionary technology and uncover its remarkable benefits.

1. Boosting Lightweight Durability

WPC profiles are renowned for their durability and eco-friendliness. However, the addition of NC Foaming Agent for WPC Profiles takes these properties to a whole new level. By incorporating NC foaming agents into WPC profiles, manufacturers can achieve an optimal balance between weight reduction and structural integrity. The foaming process creates tiny air bubbles, resulting in a lightweight material that retains its strength, making it ideal for various applications in the construction and automotive industries.

2. Enhancing Thermal Insulation

Energy efficiency has become increasingly crucial in modern times, and NC Foaming Agent for WPC Profiles offer an extraordinary solution. When applied to WPC profiles, these agents introduce excellent thermal insulation properties, reducing heat transfer and improving energy conservation. Imagine the possibilities of using NC foamed WPC profiles for doors, windows, and wall cladding, providing superb insulation while maintaining a sleek, aesthetically pleasing appearance.