Products

NC foaming agent for SPC board

Product Details

NC blowing agent is a kind of endothermic foaming agent, blow off the gas gently, make foaming process is easy to control, it can guarantee the stability of the performance especially in thicker size and complex shape dynamic molding process of foam products.

Technical data

| Product Code | Appearance | Gas evolution(ml/g) | Decomposition temperature (°C) |

| SNN-130 | white powder | 130-145 | 160-165 |

| SNN-140 | white powder | 140-160 | 165-170 |

| SNN-160 | white powder | 145-160 | 170-180 |

Feature

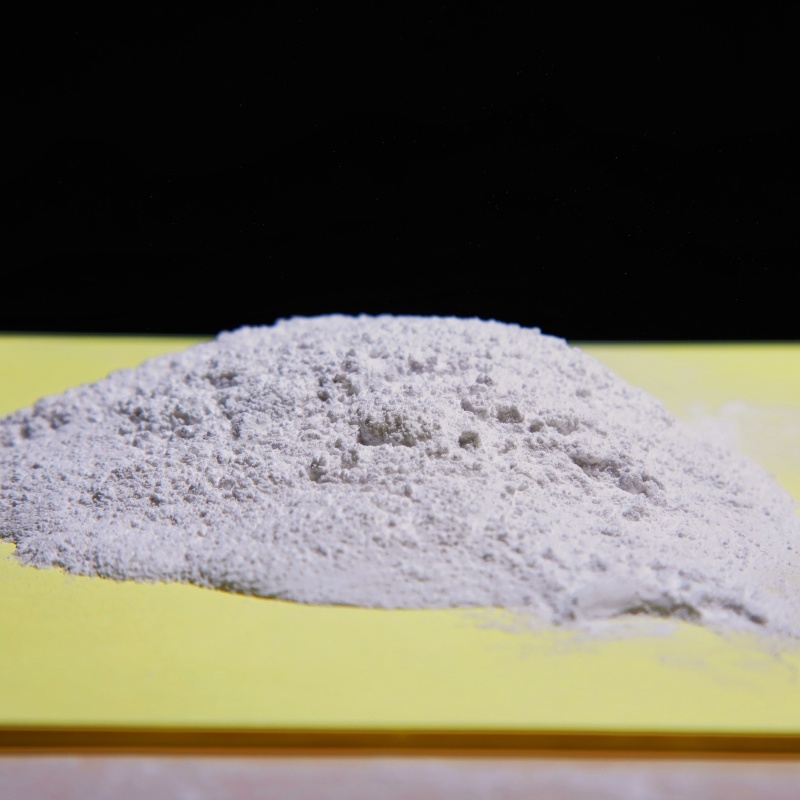

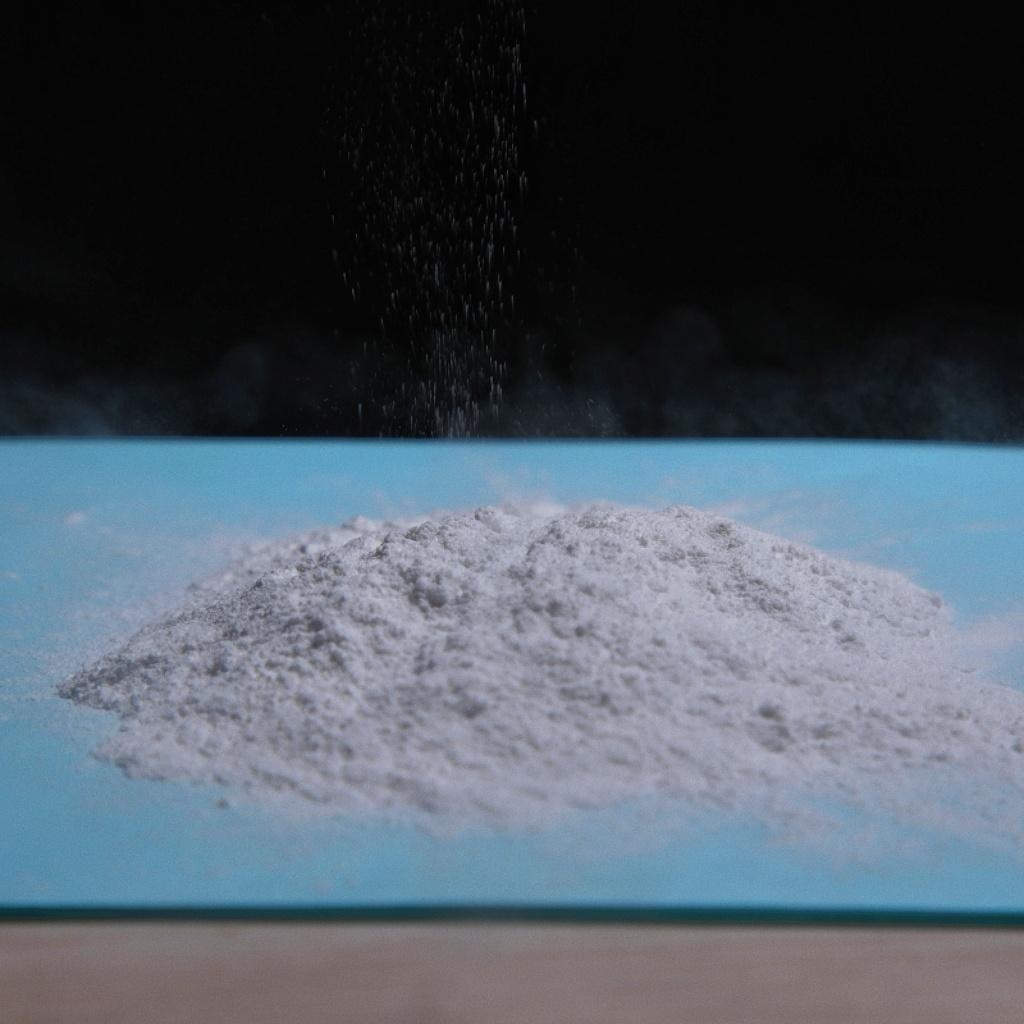

1. This product is white powder.

2. This product has excellent compatibility and good compatibility with AC foaming agent; it accelerates the decomposition of foaming agent, improves processing speed and reduces production cost.

3. This product can significantly improve the durability and aging resistance of the product, and ensure the long-term stability of the product.

4. This product can significantly improve the surface finish of the product. It does not show pinholes, air streaks and melting and cracking on the product surface.

5. This product is non-toxic, non-corrosive and environmentally friendly solid powder, no mechanical impurities, and non-dangerous goods.

Applications

High-grade cabinet boards, advertising boards and other products that require whiteness

Packaging and storage

25kg/bag PP woven outer bag lined with PE inner bag

Exploring the Science of NC Foaming Agent for SPC Board in Flooring Applications

Introduction

The modern flooring industry is always on the lookout for new and improved materials that offer enhanced performance and durability. One such innovation is Stone Plastic Composite (SPC) boards, which have gained popularity in recent years for their numerous advantages. A critical component in the production of these boards is the NC foaming agent for SPC board. This article will delve into the science behind this foaming agent, its benefits, and its impact on the flooring industry.

The Science of NC Foaming Agent for SPC Board

NC foaming agent for SPC board is a chemical compound that, when added to the PVC resin mixture during the manufacturing process, produces a foam-like structure within the SPC boards. The process involves the decomposition of the foaming agent, which releases nitrogen gas that forms bubbles within the PVC resin mixture. These bubbles create a lightweight, yet rigid foam structure, which gives SPC boards their unique properties.

Applications of NC Foaming Agent for SPC Board

Home renovations: The durability and low-maintenance nature of NC Foaming Agent for SPC Board make them an excellent choice for homeowners looking to upgrade their flooring during a renovation project.

New construction: SPC boards are increasingly being used in new construction projects due to their numerous advantages, such as their strength, dimensional stability, and thermal insulation properties.

Industrial flooring: The durability and rigidity of NC Foaming Agent for SPC Board make them suitable for industrial flooring applications, where they can withstand the demands of heavy machinery and high foot traffic. Hospitality venues: Hotels, restaurants, and other hospitality venues can benefit from the low-maintenance, sound insulation, and durability of SPC boards.

Advantages of NC Foaming Agent for SPC Board

Superior strength and rigidity: The foam structure created by the NC foaming agent for SPC board enhances the strength and rigidity of the final product. This results in SPC boards that are able to withstand heavy foot traffic, impact, and daily wear and tear, making them an ideal flooring solution for both residential and commercial spaces.

Enhanced dimensional stability: The NC foaming agent for SPC board improves the dimensional stability of SPC boards. This means that they are less likely to warp, buckle, or change shape due to temperature fluctuations or humidity, ensuring a stable and long-lasting flooring solution.

Improved sound insulation: The foam structure created by the NC foaming agent for SPC board also offers excellent sound insulation properties. This makes SPC flooring a great choice for rooms where noise reduction is a priority, such as bedrooms, home offices, or commercial spaces.

Low maintenance requirements: SPC boards manufactured with NC foaming agents require minimal maintenance, as they are resistant to scratches, stains, and moisture. This low-maintenance nature makes them an attractive option for busy homeowners or commercial spaces with high foot traffic.

Enhanced thermal insulation: The foam structure of SPC boards also provides superior thermal insulation, keeping spaces warm in the winter and cool in the summer. This can lead to energy savings and increased comfort for occupants.

Conclusion

NC foaming agent for SPC board has significantly impacted the flooring industry by providing an innovative material that offers numerous advantages over traditional flooring options. From improved strength and rigidity to superior thermal and sound insulation properties, SPC boards manufactured with this foaming agent have become a popular choice for a wide range of applications. As the demand for high-quality, durable flooring solutions continues to grow, the use of NC foaming agent for SPC board is expected to increase, further revolutionizing the flooring industry.

The Advantages and Applications of NC Foaming Agent for SPC Board in Modern Flooring Solutions

Introduction

The flooring industry has experienced significant growth in recent years, with technological advancements paving the way for innovative materials and techniques. One such innovation is the use of Stone Plastic Composite (SPC) boards in the production of high-quality, durable flooring solutions. In this article, we will discuss the importance of NC foaming agent for SPC board and its advantages and applications in the flooring industry.

NC foaming agent for SPC board plays a critical role in the production of SPC flooring. The agent is added to the PVC resin mixture during the manufacturing process, causing the mixture to expand and create a foam-like structure. This foam structure not only makes the SPC boards lightweight but also enhances their dimensional stability and rigidity.

Advantages of Using it

Enhanced durability: NC foaming agent for SPC board improves the overall durability of SPC flooring by providing it with a robust structure. This makes SPC boards resistant to impact, indentation, and general wear and tear, ensuring a long-lasting flooring solution.

Improved thermal insulation: The foam structure created by the NC foaming agent for SPC board offers excellent thermal insulation properties. This means that SPC flooring is capable of maintaining a comfortable temperature in various environments, making it suitable for use in both residential and commercial settings.

Superior moisture resistance: SPC boards made with the help of NC foaming agents are highly resistant to moisture, making them an ideal choice for use in damp or humid environments. This resistance to moisture also prevents the growth of mold and mildew, ensuring a healthy living space.

Easy installation: The lightweight nature of SPC boards, thanks to the NC foaming agent, makes them easier to handle and install. This reduces the overall installation time and labor costs, making SPC flooring an attractive option for both homeowners and contractors.

Environmentally friendly: NC foaming agent for SPC board is a non-toxic and eco-friendly option for the flooring industry. By choosing SPC boards made with this agent, consumers can contribute to a more sustainable and environmentally conscious construction sector.

Applications of NC Foaming Agent for SPC Board

Residential flooring: SPC boards are a popular choice for residential flooring due to their durability, ease of installation, and moisture resistance. They are suitable for use in kitchens, bathrooms, living rooms, and bedrooms.

Commercial flooring: The high-performance nature of SPC boards, enhanced by NC foaming agents, makes them ideal for commercial applications such as offices, retail spaces, and hospitality venues.

Healthcare facilities: The moisture resistance and easy-to-clean properties of SPC flooring make it a suitable choice for healthcare facilities, where hygiene and cleanliness are of utmost importance.

Educational institutions: SPC boards are an excellent flooring option for schools, colleges, and universities, thanks to their durability, low maintenance requirements, and resistance to wear and tear.

Conclusion

NC foaming agent for SPC board has revolutionized the flooring industry by offering a high-performance, eco-friendly, and versatile material for various applications. With its numerous advantages and wide range of applications, SPC flooring has become a popular choice among homeowners, contractors, and architects alike. By investing in SPC boards made with NC foaming agents, consumers can enjoy a durable, attractive, and sustainable flooring solution that meets the demands of modern living.

Buy NC foaming agent for SPC board suppliers introduce foaming agents

Buy NC foaming agent for SPC board suppliers tells you that chemical foaming agents can be divided into inorganic foaming agents and organic foaming agents. Buy NC foaming agent for SPC board suppliers tells you that organic foaming agents mainly include the following categories: 1. Azo compounds; 2. Sulfonylhydrazine compounds; 3. Nitroso compounds.

Buy NC foaming agent for SPC board suppliers tells you that inorganic foaming agents mainly include the following categories: Carbonate: an inorganic foaming agent, calcium carbonate, magnesium carbonate, and sodium bicarbonate are mostly used. Among them, sodium bicarbonate is a white powder with a specific gravity of 2.16. The decomposition temperature is about 100-140°C, part of CO2 is released, and all CO2 is lost at 270°C. Soluble in water but insoluble in alcohol.

Water glass: Sodium silicate. Buy NC foaming agent for SPC board suppliers tells you that when it is mixed with glass powder and heated to about 850°C, it will react with glass and release a lot of gas, and at the same time, it can strengthen the compressive and tensile strength of the material, mainly used as the preparation of foam glass Foaming agent used.

Silicon carbide: Buy NC foaming agent for SPC board suppliers tells you that the main foaming agent used in the current industrial production of foam glass, releases a lot of gas when sintered at 800-900 °C. Carbon black: It is also a very useful foaming agent. It emits CO2 when heated, and the foaming effect is good, but the disadvantage is that the price is relatively high.

Through the above introduction and analysis of Buy NC foaming agent for SPC board suppliers introduce foaming agents, hope it helps you.

Wholesale NC foaming agent for SPC board manufacturers introduce the types of foaming agent

Wholesale NC foaming agent for SPC board manufacturers tells you that the foaming agent is a substance that makes the target material form pores, and it can be divided into three categories: chemical foaming agent, physical foaming agent, and surfactant.

Wholesale NC foaming agent for SPC board manufacturers tells you that chemical foaming agents are compounds that release gases such as carbon dioxide and nitrogen after thermal decomposition, and form pores in the polymer composition; physical foaming agents are foam pores that pass through A change in the physical form of a substance, that is, a compound formed by the expansion of a compressed gas, the volatilization of a liquid, or the dissolution of a solid.

Wholesale NC foaming agents for SPC board manufacturers tell you that the foaming agent has high surface activity, which can effectively reduce the surface tension of the liquid, and arrange the double electron layer on the surface of the liquid film to surround the air, forming bubbles, and then composed of single bubbles Foam.

Through the above introduction and analysis of Wholesale NC foaming agent for SPC board manufacturers introduce the types of foaming agent, hope it helps you.