Products

Lead salt stabilizer for PVC WPC SPC board

Product Details

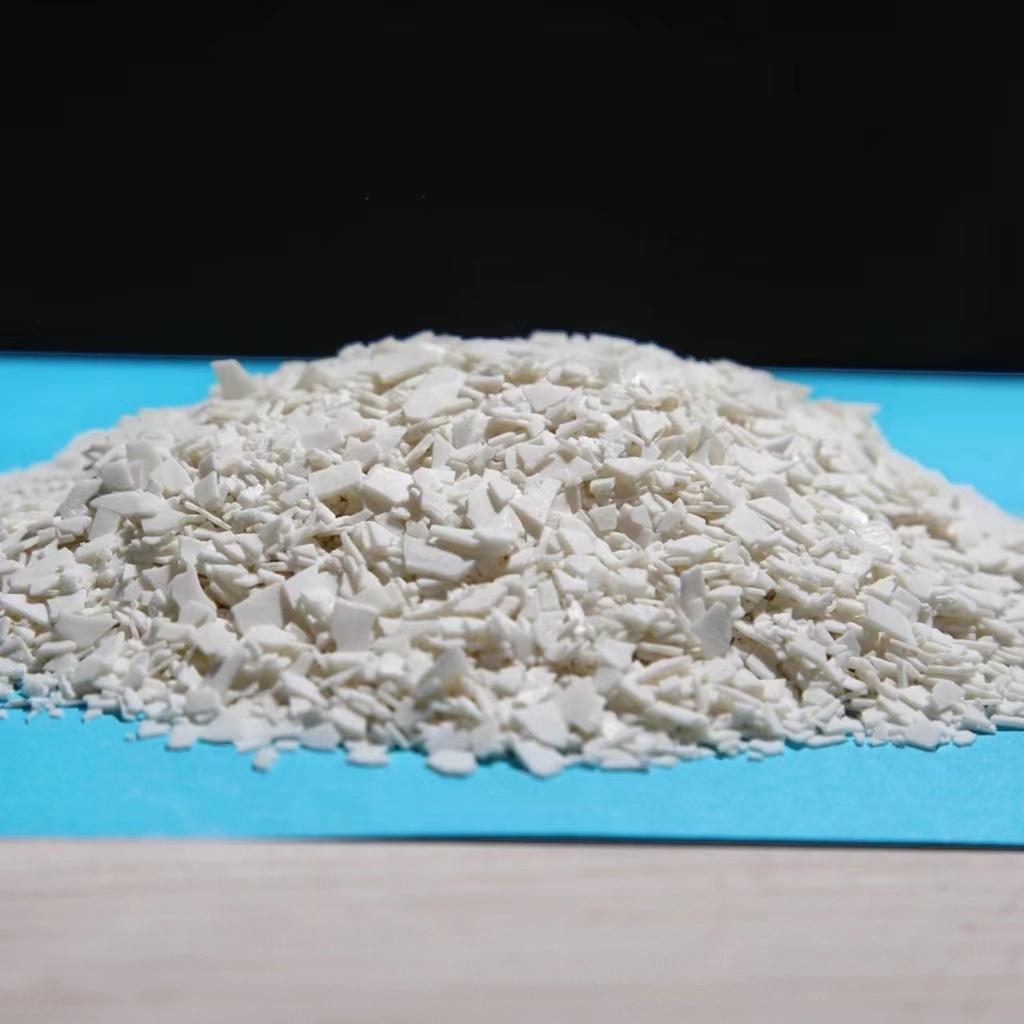

The lead salt stabilizer for PVC WPC SPC board is white or slightly yellow dust. Soluble in toluene, ethanol and other solvents, insoluble in water, will decompose in case of strong acid

Technical indicators

| Item | Unit | Specifications |

| Appearance | / | White or slightly yellow powder |

| Volatile Substances | % | ≦1 |

| melting point | ℃ | ≥80 |

| Density | g/cc | 1.32 |

| Amount (in PVC) | % | 3 to 5 |

Features

This product has good initial coloration; long thermal stability; good metal stripping; good compatibility; improved melt strength; increased surface gloss.

Applications

PVC advertising board, cabinet board, ecological wood (cedar)

Packaging and storage

25kg/bag PP woven outer bag lined with PE inner bag

How To Choose PVC Heat Stabilizer In Plastic Formulation Design

The main reason for adding PVC heat stabilizer in plastic formulation design is that it can capture the autocatalytic HCL released by PVC resin, which can be reflected by the addition of unstable polyene structure generated by PVC resin, so as to prevent or reduce the decomposition of PVC resin. In order to better solve the PVC processing may occur in a variety of undesirable phenomena.

The PVC heat stabilizer selected in the general formula should be considered according to its own characteristics, functions and requirements of products. For example, the lead salt compound stabilizer mainly used in hard products has the characteristics of good thermal stabilizer, excellent electrical performance and low price. Disadvantages are toxicity, easy to pollute products, can only produce opaque products.

Calcium zinc composite stabilizer can be used as a non-toxic stabilizer, used in food packaging and medical equipment, drug packaging, but its stability is relatively low, calcium stabilizer dosage when poor transparency, easy to spray frost. Calcium and zinc composite stabilizer generally use polyol and antioxidant to improve its performance.

The above two types of PVC thermal stabilizers are commonly used at present, but the practical application is not limited to this, but also contains organic tin thermal stabilizers, epoxy stabilizers, rare earth stabilizers and hydrotalcite stabilizers.